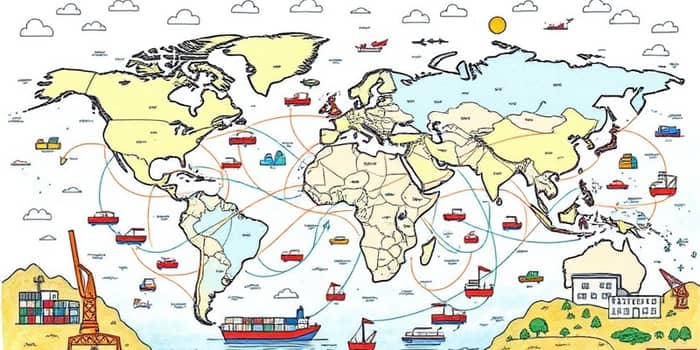

In an era marked by sudden disruptions—from geopolitical tensions to extreme weather—businesses worldwide are reimagining their supply networks. By embracing diversification, companies aim to build resilient, adaptive global systems that can withstand shocks and sustain growth.

Supply chain disruption has shifted from rare crises to everyday challenges. Trade wars, tariffs, political shifts and environmental events now routinely interrupt flows of goods. As a result, supply chain management has evolved from a back-office support role to a C-suite strategic imperative.

Organizations recognize that relying on a single region or supplier exposes them to cascading failures. In response, firms are transitioning from a solely cost-driven mindset to one focused on back-office function to strategic priority, ensuring continuity even under duress.

Achieving robustness requires a multifaceted approach. Leaders are balancing the traditional goals of cost and speed with new objectives, including risk mitigation and environmental stewardship. This shift emphasizes balancing cost, efficiency with resilience across sourcing, production and logistics.

By spreading risk across multiple suppliers and regions, companies can maintain operations even if one link fails. Flexible agreements and continuous monitoring further enable rapid shifts in response to emerging threats.

Global innovators demonstrate the power of diversification in action. They combine strategic sourcing with cutting-edge tools to create supply networks that absorb shocks and adapt swiftly.

Apple sources components from China, Vietnam and India, leveraging a multi-country supplier framework and dual sourcing to minimize impacts from trade disputes and lockdowns.

Toyota introduced dual-sourcing following the 2011 Japan earthquake, ensuring that critical parts could be obtained from alternative locations, reducing downtime and safeguarding production.

Unilever champions regional, sustainable sourcing. By partnering with suppliers close to key markets, the company cuts transportation risks while reinforcing its brand commitment to ethical and eco-friendly practices.

Turning strategy into action demands disciplined planning and execution. Firms must leverage advanced technologies to drive insights and ensure agility at every decision point, supported by AI and real-time analytics integration for end-to-end visibility.

Throughout this process, teams must maintain clear governance structures and cross-functional collaboration. Regular feedback loops help refine strategies and address challenges proactively.

The following table highlights core diversification approaches and their proven benefits.

As companies look ahead, the challenge will be to sustain this resilience without sacrificing operational efficiency. Leaders must embrace proactive risk assessment and contingency planning to anticipate disruptions before they escalate.

Continuous improvement is paramount, driven by continuous reviews and agile adjustments that refine supplier portfolios, logistics networks and technology investments.

Ultimately, the most resilient supply chains will be those that combine strategic foresight with operational agility. By diversifying thoughtfully and harnessing innovative tools, businesses can transform uncertainty into competitive advantage and drive long-term sustainable growth.

References